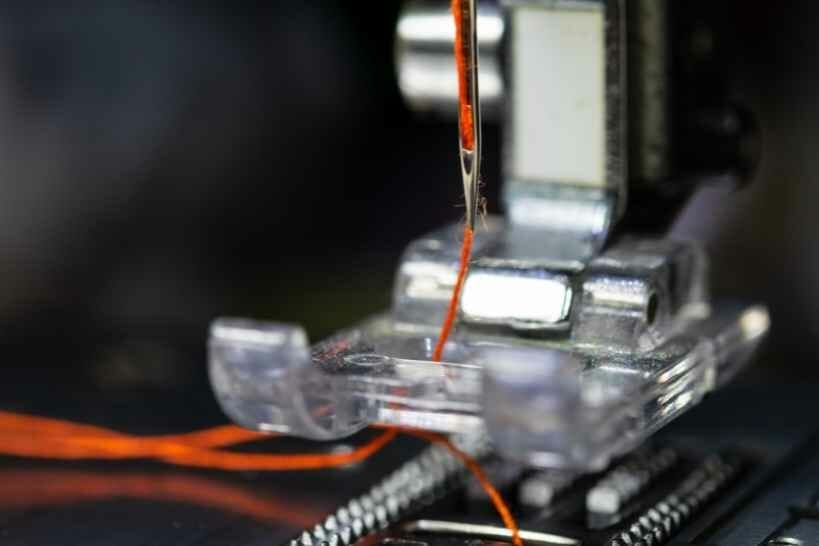

How Does A Needle Feed Sewing Machine Work & What Makes It Different?

If your looking into buying a sewing machine, you might have come across a variety of different models with varying needle feed mechanisms.

A needle feed sewing machine in particular is often found most on industrial sewing machine types, especially when working with double needles, it’s used as the primary element for feeding the needle through the fabric, going forward and reverse.

We’ve put together a small guide below which will discuss what these sewing machines are used for, different types of sewing machine feeding mechanisms as well as what to do if your sewing machine is not feeding.

What Are Needle Feed Sewing Machines Used For?

Needle feed sewing machines are typically used for industrial purposes since they allow the machine to stitch together both thin and thick fabrics without uniform thickness.

They are also used as industrial machines thanks to their high speed and ease of use, since the fabric is fed through the needle feed machine at the same time as the needle and the feed dog, meaning you don’t have to wait for the top and lower layers.

The Different Feeding Mechanisms On Sewing Machines

When on the hunt for a new sewing machine, you’ll realise that every model has to have a form of feeding to work, however, feeding can differ according to the machine you choose.

We’ve discussed each type of feeding mechanism you can find on sewing machines below.

Drop Feed Mechanism

The most common feeding mechanism you find on a normal machine is the drop feed mechanism, it uses feed dogs underneath the feet of the regular machine to move the fabric through allowing you to control the direction and length of the stitch.

This regular feed machine differs from others since the feeding occurs while the needle is out of the fabric, a stitch is created, the needle comes up and then the feed dog takes the fabric and feeds it through the machine again.

The advantage of the drop feed mechanism is that these machines are often more affordable and work great for fashion projects with thin fabrics, they do however struggle sewing thicker fabrics and can get an uneven stitch length.

Puller Feed Mechanism

This is similar to the drop feed mechanism except it differs slightly since it has supporting rollers that pull and apply pressure to the fabric to help it move through the machine. This roller behind the presser foot pulls it at the same speed as the feed dog.

The mechanism is best suited to runs or long radius curves, the downfalls of them are that they are expensive heavy machines, and they are also bad for reverse sewing or sewing tight and delicate designs with corners.

Walking Foot Feed Mechanism

Walking foots work with their teeth and feed dogs to feed the fabric through the foot machines then release both the top and bottom at the same time increasing machine speed.

With these walking foot sewing machines, it prevents the fabric from puckering up as it is one movement in unison, working great for when you are trying to sew multiple layers of fabric together of different types.

A walking foot modern machine is an excellent choice for sewing projects such as heavy canvas or upholstery. It is not however ideal for sewing thin fabrics and can even damage delicate designs.

Compound Walking Foot Feed Mechanism

This is also known as a triple feed, compound walking foot or as we discussed above, a needle feed machine. These types of sewing foot machines have a two-part system where the needle and footwork together pull fabric forward, backwards and side to side.

Due to this unison, fabric never shifts and produces very neat stitches, handling leather materials and upholstery items. The main downfall of this feed mechanism is that it can only perform straight stitches and can struggle with uneven material.

What To Do If Your Needle Feed Sewing Machine Is Not Feeding

If your needle feed machine is not feeding then it could be due to several different issues, but most can be easily remedied, no matter the feeding mechanism your sewing machine has.

We’ve listed some troubleshooting and solutions below.

- The machine is not threaded right – Your thread can get a knot when you are threading the sewing machine or winding the bobbin. In this case, you will need to re-thread your machine from the beginning.

- Tension is too tight – Ensure you are using the right tension of thread for the fabric that you are sewing, your tension should be even in both the upper and bobbin, you can use the tension dial to adjust your upper thread with ease.

- Your feed dogs are down or worn – Your feed dogs might be too low and need to be raised, they should also be sharp, if they are worn down on an older sewing machine then they might need to be replaced.

- Too thick fabric – Too many fabric layers or fabric that is too thick can jam your triple feed machine, you might need to adjust your foot pressure to be able to sew properly or use a normal walking foot attachment.

- Presser’s foot is not down – Your presser foot should always be lowered before sewing, if not your feed dogs will not be able to grab on to fabric.

- It needs cleaning – A blocked bobbin case that is full of lint can stop stitches from forming properly and prevent your needle from moving forward during sewing, simply clean the bobbin then retry your machine.

- Zero stitch length – If you’ve recently made a buttonhole with your sewing machine then your stitch length might be set at zero, this means it will not move your fabric back or forwards.

Frequently Asked Questions About Needle Feed Sewing Machines

What are the pros and cons of needle feed sewing machines?

Needle feed sewing machines are excellent for producing neat stitches and sewing fabrics such as leather without fabric puckering together. The downfall of them however is that these sewing machines cannot do any other stitches than just straight stitches.

Is a needle feed machine a straight stitch machine?

Yes, a needle feed machine is a straight stitch machine and cannot perform any kind of other stitches.

What are the best sewing machine feeding mechanisms for thick fabrics?

The best feeding mechanisms for thick fabrics are walking foot mechanisms since they can handle multiple layers of different fabrics.

Final Words

To conclude, a needle feed sewing machine is also known as a triple-needle machine and walking compound foot machine. They work by using the needle at the same time as the feed dog to feed fabric and are best found in industrial machines for handling heavier fabrics like leather.

We would not suggest using a needle sewing machine foot for sewing delicate fabrics or anything other than a straight stitch.